Optimizing Support Structures for Biological Pharmaceutical Equipment

Applications of Tubing, Fittings, and Valves in Biopharmaceutical Equipment

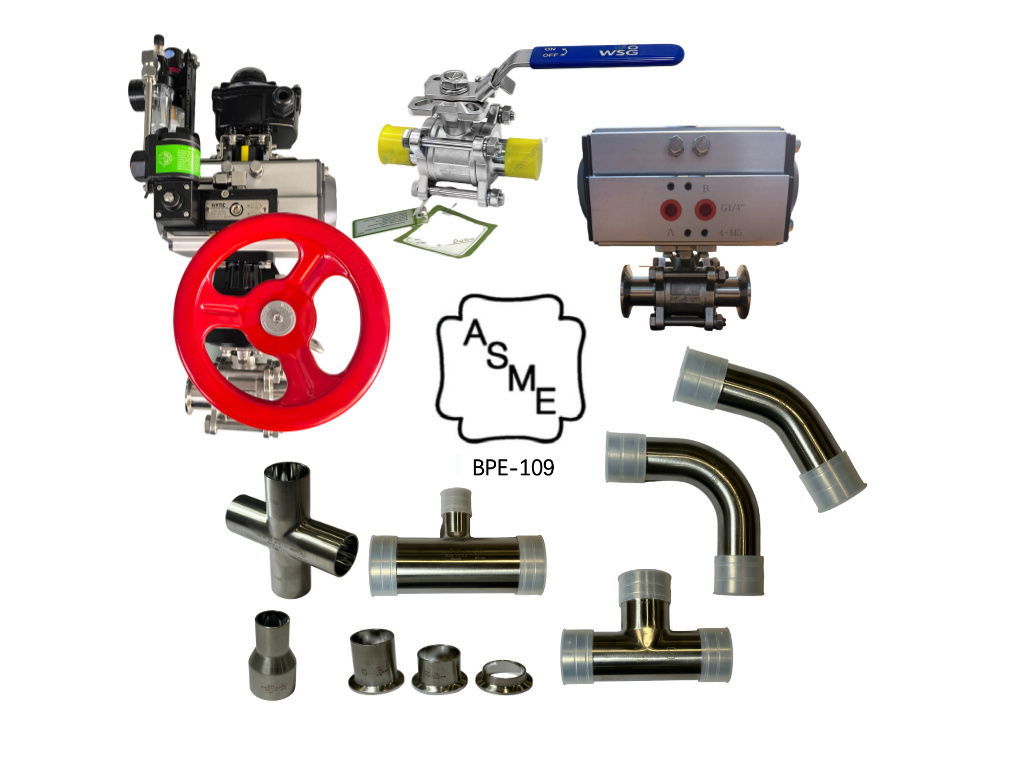

In biopharmaceutical equipment, tubing, fittings, and valves are essential components that play critical roles in ensuring the smooth and reliable operation of various processes, from fluid transfer to system control. Their proper selection and application are vital for maintaining product quality, preventing contamination, and meeting strict regulatory standards.

In biopharmaceutical equipment, tubing, fittings, and valves are essential components that play critical roles in ensuring the smooth and reliable operation of various processes, from fluid transfer to system control. Their proper selection and application are vital for maintaining product quality, preventing contamination, and meeting strict regulatory standards.Tubing

Tubing serves as the primary pathway for the transfer of fluids, such as cell cultures, media, buffers, and pharmaceutical ingredients, within biopharmaceutical equipment. It is designed to meet high-purity requirements, with materials like silicone, fluoropolymers (e.g., PTFE), and stainless steel being commonly used.

In bioreactors, tubing connects different parts of the system, enabling the transfer of nutrients into the reactor and the removal of waste products. It must be flexible enough to accommodate the movement of components during operation while resisting chemical corrosion from the various fluids it comes into contact with. In chromatography systems, tubing is used to carry samples and mobile phases between columns, detectors, and other components, ensuring minimal sample loss and efficient separation. Additionally, in filling and packaging lines, tubing facilitates the precise transfer of pharmaceutical products into vials, syringes, or other containers, maintaining sterility throughout the process.

Fittings

Fittings are used to connect tubing to various components of biopharmaceutical equipment, creating leak-tight and secure joints. They come in a variety of types, including compression fittings, barbed fittings, and quick-connect fittings, each suitable for different applications and tubing materials.

In fluid handling systems, fittings ensure that there is no leakage of fluids, which is crucial for preventing contamination and maintaining the integrity of the process. For example, in ultrafiltration and diafiltration systems, fittings connect the tubing to membrane modules, ensuring efficient fluid flow and preventing bypass. They also allow for easy assembly and disassembly of equipment, facilitating maintenance, cleaning, and replacement of components. Fittings made from materials compatible with the fluids and cleaning agents used are essential to avoid chemical reactions that could compromise product quality.

Valves

Valves are responsible for controlling the flow, pressure, and direction of fluids in biopharmaceutical equipment. They play a key role in regulating processes, such as starting or stopping fluid flow, adjusting flow rates, and preventing backflow.

In bioreactors, valves are used to control the addition of gases (e.g., oxygen and carbon dioxide) to maintain optimal cell growth conditions, as well as to regulate the flow of media and other fluids into and out of the reactor. In purification processes, such as chromatography and filtration, valves direct the flow of samples and buffers through different columns or filters, enabling precise separation and purification. Check valves are commonly used to prevent backflow, which could cause contamination or disrupt the process. Additionally, in cleaning-in-place (CIP) and sterilization-in-place (SIP) systems, valves control the flow of cleaning and sterilizing agents, ensuring that all parts of the equipment are properly cleaned and sterilized.

In summary, tubing, fittings, and valves are indispensable components in biopharmaceutical equipment. Their proper functioning ensures the efficient, safe, and reliable transfer and control of fluids, which is essential for the production of high-quality pharmaceutical products that meet regulatory requirements.

RELATED PRODUCTS