Welding Frame

Welding Frame for presses machine (WhatsApp:+86 15862674375)

Unit Price :

Stoke:

隐藏域元素占位

Introductions :

This comes from a project of our American client. YWKE frame is a critical structural component that forms the backbone of a press, responsible for withstanding extreme mechanical forces (e.g., stamping, forging, or bending) during operation. Unlike cast frames, welded frames are fabricated by joining steel plates/sections via welding, offering advantages like design flexibility, lighter weight, and shorter production cycles. Below is a detailed overview of its key aspects:

Core Functions of a Press Machine Welding Frame

Force Bearing: Absorbs and distributes high static/dynamic loads generated during pressing operations (ranging from tons to thousands of tons).

Structural Stability: Maintains rigidity to prevent deformation, ensuring precision in workpiece processing.

Component Integration: Provides mounting points for key press components (e.g., crankshafts, cylinders, dies, and control systems).

Key Design Considerations

The design of a welded press frame must balance strength, rigidity, and manufacturability. Key factors include:

a. Load Analysis

Static loads: Steady forces from workpiece deformation (e.g., in cold stamping).

Dynamic loads: Impact forces from rapid ram movement or sudden material resistance (critical for avoiding fatigue failure).

Force distribution: Frame geometry (e.g., closed vs. open structures) must ensure uniform load spread to minimize stress concentration.

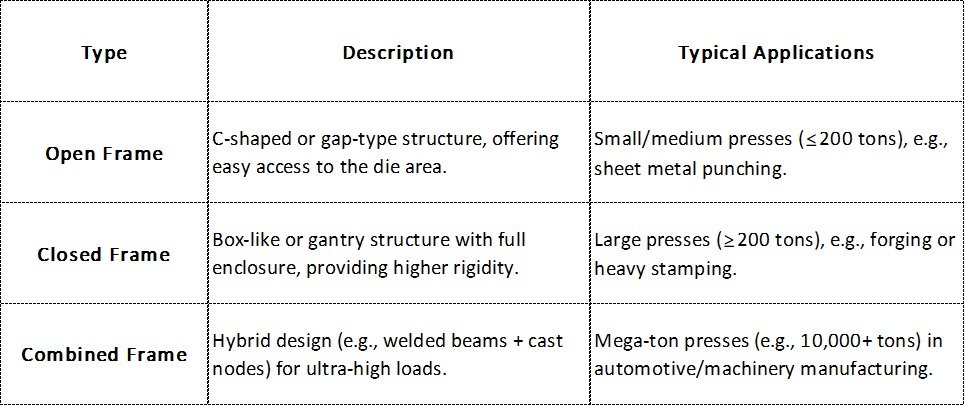

b. Structural Types

Press frames are categorized by their structure, each suited for specific applications:

c. Weldability & Stress Reduction

Material selection: Weldable steels (e.g., Q355B, S355JR) with good toughness and strength are preferred. High-strength low-alloy (HSLA) steels are used for large frames to reduce weight.

Avoiding stress concentration: Fillet welds, rounded corners, and gradual thickness transitions in plate joints minimize crack risks.

Symmetric design: Balanced geometry reduces uneven welding deformation.

Welding Processes & Techniques

The choice of welding method depends on frame size, material thickness, and precision requirements:

Submerged Arc Welding (SAW): Ideal for thick plates (≥10mm) in large frames, offering high deposition rates and strong, uniform welds.

Gas Metal Arc Welding (GMAW/MIG): Used for medium-thickness sections, providing flexibility in complex joints.

Shielded Metal Arc Welding (SMAW/MMA): Suitable for small or hard-to-reach joints in intricate frame details.

Welding sequence: Multi-pass welding with alternating directions (e.g., from center to edges) reduces residual stress and warpage.

Post-Welding Treatments

To ensure frame performance, post-weld processes are critical:

Stress relief annealing: Heating the frame to 600–650°C and slow cooling to eliminate residual stresses from welding (prevents long-term deformation).

Shot blasting: Cleans weld surfaces and improves fatigue resistance by inducing compressive stress.

Machining: Precision milling/grinding of mating surfaces (e.g., ram guides, bed rails) to meet dimensional tolerances (often ±0.1mm/m).

Quality Control

Non-Destructive Testing (NDT):

- Ultrasonic Testing (UT) to detect internal weld defects (e.g., cracks, porosity).

- Magnetic Particle Testing (MT) for surface cracks in ferromagnetic materials.

Mechanical testing: Tensile and impact tests on weld samples to verify strength/toughness.

Dimensional inspection: Using mechanical coordinates to check frame straightness, parallelism, and squareness.

Advantages Over Cast Frames

Design flexibility: Easily customized for unique press configurations.

Cost efficiency: Shorter production cycles (no mold casting) and higher material utilization.

Weight reduction: Optimized plate thicknesses reduce overall machine weight, lowering energy consumption.

In summary, YWKE’s welding frame is essential for press machine reliability, processing precision, safety, and service life.

Relevant salespersons:

Ashley

Customer Manager

Specialize: Mechanical equipment parts

Area: Europe, Asia

RELATED PRODUCTS

Online Message